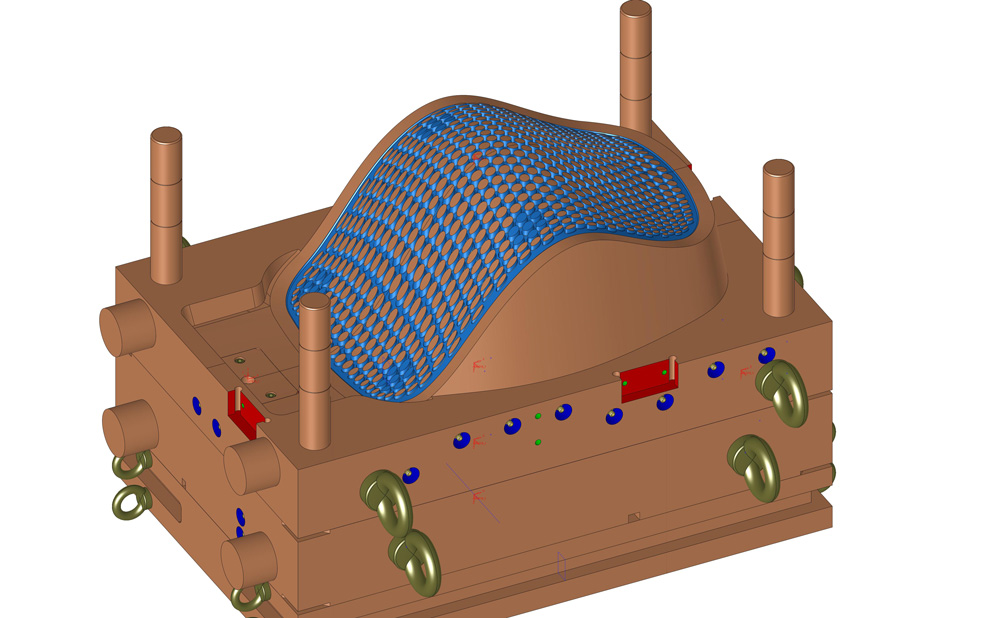

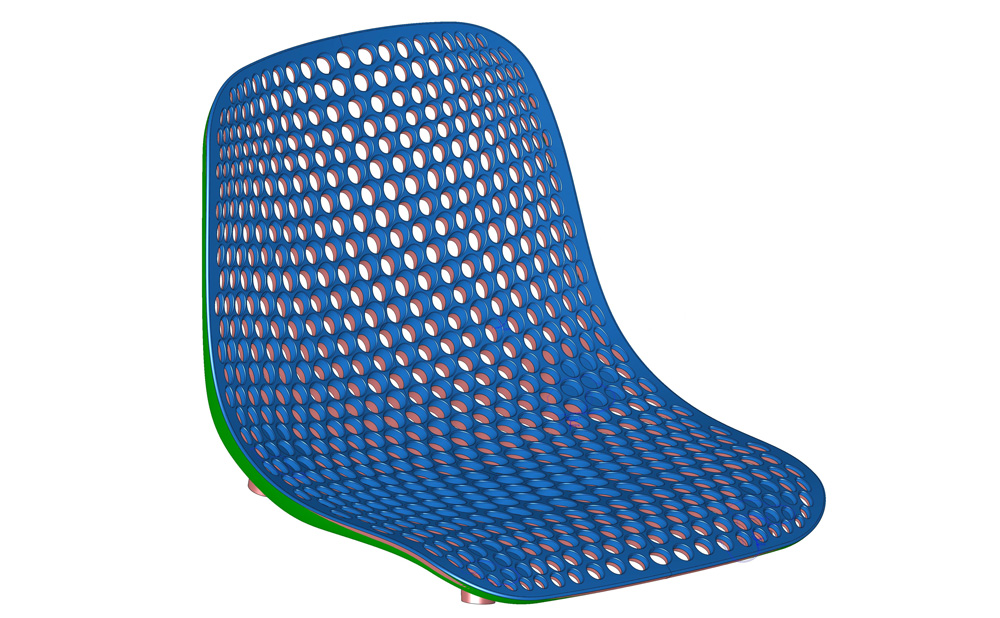

Mold design

The technical office of the Nardello Stampi company is equipped with high-profile and continuously evolving software. In order to significantly reduce the time and the margins of error, the design of the mold takes place completely in a 3D environment; subsequently the mathematics of the single details that make up the mold are transmitted to the CAM stations, where the tool paths are generated directly on the 3D model of the particular. The new technologies available make it possible to virtualize the entire manufacturing process, thus making it possible to work even with unmanned processes and significantly increasing the company's production capacity.